This page provides a detailed overview of the cultivated meat value chain map. It aims to help users understand the workflow involved in producing cultivated meat, discusses the various jobs required at each stage, identifies the necessary skills for these roles, and offers guidance on where to acquire these skills. Whether you are a student, a professional looking to transition into the industry, or simply curious about the process, this page will help guide you in the right direction.

Cultivated meat is genuine animal meat cultivated directly from cells in a controlled environment. The production process begins by sourcing animal cells through a minimally invasive biopsy. These cells are then cultured in a nutrient-rich medium, enabling them to proliferate and differentiate into muscle tissue, fat, and other components that make up conventional meat. Cultivated meat is made of the same cell types arranged in the same or similar structure as animal tissues, thus replicating the sensory and nutritional profiles of conventional meat. This technology holds the promise of providing meat without the associated drawbacks of conventional animal agriculture, such as environmental degradation, zoonotic disease risks, and resource inefficiencies.

The cultivated meat industry is rapidly evolving and requires a diverse talent pool to drive innovation and bring products to market. Professionals from various disciplines, including bioprocess engineering, molecular biology, tissue engineering, food science, and regulatory affairs, are essential to overcoming the technical and logistical challenges involved. Expertise in cell culture, bioreactor design, scaling up production processes, and ensuring food safety and quality are critical for the industry’s success. Additionally, interdisciplinary collaboration is vital to integrate advancements from biotechnology, material science, and food technology. The need for skilled individuals is paramount as the industry scales from R&D to commercial production, to ensure that cultivated meat products are safe, affordable, and accessible to consumers.

Working in the cultivated meat industry offers a unique opportunity to make a significant, positive impact on the world. Cultivated meat production has the potential to drastically reduce greenhouse gas emissions, land use, and water consumption compared to conventional livestock farming. By eliminating the need for raising and slaughtering animals, this technology can also improve animal welfare and reduce the spread of zoonotic diseases. Furthermore, it can contribute to global food security by providing a sustainable source of protein for our growing human population. Professionals in this field are not only advancing scientific and technological frontiers but also contributing to a more sustainable and secure food system.

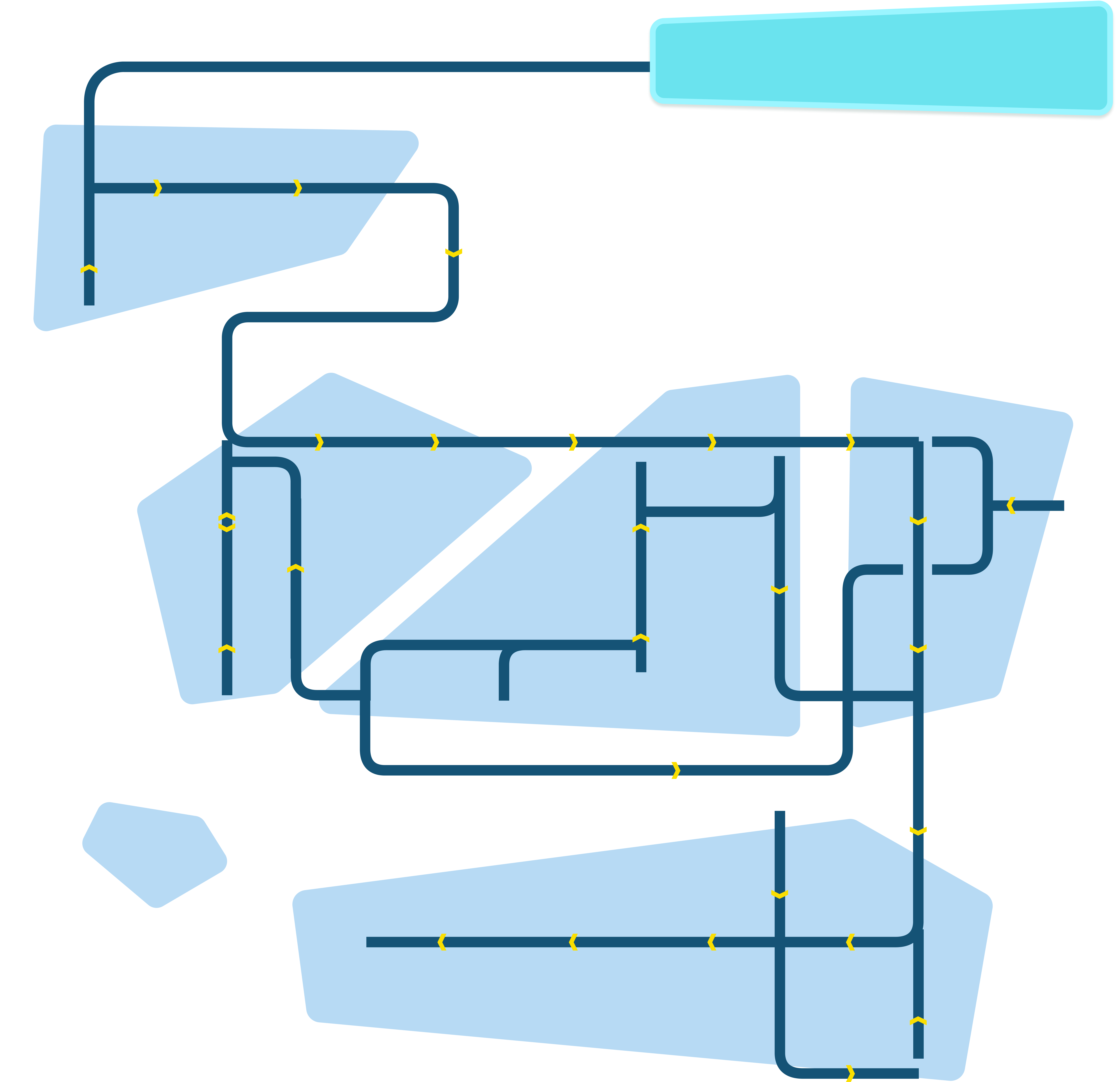

The technology value chain map outlines the step-by-step process of cultivated meat production. Users can click on each bubble to learn more about the workflow, equipment used, and job archetypes associated with that step of the value chain. The map is divided into key stages of development, making it easier to follow the flow of work that brings cultivated meat from cell isolation to market-ready products.

The technology value chain map outlines the step-by-step process involved in cultivated meat production. Users can click on each step to learn more about the specific activities, equipment used, and jobs associated with that stage. The map is divided into key stages of development, making it easier to follow the flow of work and understand the intricate processes that bring cultivated meat from cell isolation to market-ready products.

This section explores the various job archetypes within the cultivated meat industry. It provides detailed descriptions of each role, highlights their responsibilities, the skills required, and the typical backgrounds that are a good fit. Additionally, it offers insights on where to bridge any skill gaps, making it a valuable resource for those looking to enter or advance within the industry.

Bioprocess Engineers design and optimise the processes that turn cells into meat products. They focus on developing scalable and efficient systems for cell culture, including bioreactors and fermentation processes. They ensure that conditions for cell growth are optimal, such as maintaining the correct temperature, pH, and nutrient supply, to maximise cell proliferation and differentiation.

In their daily operations, Bioprocess Engineers collaborate closely with Cell Biologists to understand the specific requirements of the cell lines being used. They are responsible for scaling up the production from laboratory settings to pilot and commercial scales, while ensuring consistency and quality throughout the process. This involves troubleshooting, optimising bioprocess parameters, and integrating automation for efficiency and reproducibility.

The end goal for a Bioprocess Engineer is to develop robust, cost-effective, and scalable processes that can produce high-quality cultivated meat. They need to have a deep understanding of chemical engineering principles, cell biology, and process control. Skills in bioreactor design, process optimisation, and data analysis are crucial for their role, as is the ability to work collaboratively with multidisciplinary teams.

Discover more global alternative protein courses and programmes through GFI’s comprehensive Alternative Protein Course Database.

Use this database to find up-to-date listings of available positions in the alternative protein ecosystem, including at GFI’s international affiliates. We also recommend exploring the Tälist and Alt Protein Careers job boards, which highlight a vast array of high-impact opportunities in the field.

Tissue Engineers are crucial in developing the structural components of cultivated meat. They work on creating scaffolds and matrices that support cell attachment, growth, and differentiation, mimicking the natural environment of animal tissues. Their role involves designing biocompatible materials and optimising conditions to ensure that cells can form structured tissues that resemble conventional meat.

On a daily basis, Tissue Engineers conduct experiments to test different scaffold materials and their interactions with cells. They collaborate with Cell Biologists to understand the cellular requirements and with Bioprocess Engineers to integrate these scaffolds into larger production systems. Their projects often involve using advanced techniques like 3D printing, electrospinning, and hydrogel synthesis to create scaffolds that promote cell alignment and tissue formation.

The end goal for a Tissue Engineer is to develop scaffolds that enable the production of high-quality, structured cultivated meat products. They need expertise in materials science, cell biology, and engineering principles. Skills in biomaterials development, tissue engineering techniques, and cell culture are essential for their role, as well as the ability to innovate and solve complex biological problems.

Discover more global alternative protein courses and programmes through GFI’s comprehensive Alternative Protein Course Database.

Use this database to find up-to-date listings of available positions in the alternative protein ecosystem, including at GFI’s international affiliates. We also recommend exploring the Tälist and Alt Protein Careers job boards, which highlight a vast array of high-impact opportunities in the field.

Cell Biologists are fundamental to the cultivated meat industry by focusing on understanding and optimising the growth and behaviour of cells used in meat production. They study cell metabolism, growth conditions, and genetic characteristics to ensure that the cells are healthy, productive, and capable of differentiating into desired tissue types. Their responsibilities include developing and maintaining cell cultures, optimising growth media, and performing genetic modifications to enhance cell performance.

In their daily operations, Cell Biologists isolate and characterise different cell strains, monitor cell growth and viability, and optimise culture conditions to support large-scale production. They work closely with Bioprocess Engineers to ensure cells perform well in bioreactors and with Tissue Engineers to develop scaffolds that support cell growth. Their projects often involve genetic engineering, metabolic profiling, and high-throughput screening to identify and optimise the best cell lines for production.

The end goal for a Cell Biologist is to develop robust, high-yield cell lines that produce cultivated meat efficiently. They need strong analytical skills, proficiency in molecular biology techniques, and a deep understanding of cell physiology and genetics. Technical skills in cell culture, genetic manipulation, and bioinformatics are crucial for their role.

Discover more global alternative protein courses and programmes through GFI’s comprehensive Alternative Protein Course Database.

Use this database to find up-to-date listings of available positions in the alternative protein ecosystem, including at GFI’s international affiliates. We also recommend exploring the Tälist and Alt Protein Careers job boards, which highlight a vast array of high-impact opportunities in the field.

Professionals in Regulatory Affairs are essential for ensuring that the processes and products in the cultivated meat industry comply with all relevant regulations and standards. They navigate the complex landscape of local, national, and international regulations to ensure that cultivated meat products are safe and legally compliant. Their responsibilities include preparing and submitting regulatory documents, coordinating with regulatory bodies, and keeping the company updated on regulatory changes.

On a daily basis, Regulatory Affairs professionals gather and compile data on product safety, efficacy, and quality. They work closely with quality assurance teams to ensure that all processes meet regulatory standards and with R&D teams to ensure that new products are developed in compliance with regulatory requirements. Their projects often involve conducting risk assessments, managing regulatory submissions, and overseeing product labelling and marketing to ensure compliance.

The end goal for Regulatory Affairs professionals is to achieve regulatory approval for cultivated meat products and maintain compliance throughout the product life cycle. They need strong analytical and organisational skills, a thorough understanding of regulatory frameworks, and the ability to communicate effectively with regulatory authorities. Technical skills in regulatory documentation, risk assessment, and compliance auditing are essential.

Discover more global alternative protein courses and programmes through GFI’s comprehensive Alternative Protein Course Database.

Use this database to find up-to-date listings of available positions in the alternative protein ecosystem, including at GFI’s international affiliates. We also recommend exploring the Tälist and Alt Protein Careers job boards, which highlight a vast array of high-impact opportunities in the field.

Job Role and Functions: Quality Assurance (QA) and Quality Control (QC) professionals are critical in maintaining the safety, efficacy, and consistency of cultivated meat products. QA focuses on preventing defects through process improvement and adherence to quality standards, while QC involves testing products to ensure they meet specified criteria. Their responsibilities include developing quality management systems, conducting audits, and performing routine product testing.

In their daily operations, QA/QC professionals design and implement quality management protocols, conduct inspections and audits of production processes, and test samples of raw materials and finished products. They work closely with production teams to ensure that quality standards are maintained throughout the manufacturing process and with Regulatory Affairs to ensure compliance with regulations. Their projects often involve developing Standard Operating Procedures (SOPs), conducting root cause analysis of quality issues, and implementing corrective actions.

The end goal for QA/QC professionals is to ensure that all cultivated meat products are safe, effective, and of high quality. They need strong analytical skills, attention to detail, and a thorough understanding of quality management principles. Technical skills in analytical chemistry, microbiology, and quality management systems are essential for their role.

Discover more global alternative protein courses and programmes through GFI’s comprehensive Alternative Protein Course Database.

Use this database to find up-to-date listings of available positions in the alternative protein ecosystem, including at GFI’s international affiliates. We also recommend exploring the Tälist and Alt Protein Careers job boards, which highlight a vast array of high-impact opportunities in the field.

As a subscriber, you’ll receive GFI APAC’s monthly newsletter as well as occasional updates and opportunities to support and get involved in our work. You may unsubscribe at any time. Please see our Privacy Policy for more details

"*" indicates required fields

"*" indicates required fields

As a subscriber, you’ll receive GFI APAC’s monthly newsletter as well as occasional updates and opportunities to support and get involved in our work. You may unsubscribe at any time. Please see our Privacy Policy for more details

Once a suitable donor animal is selected, the next step involves obtaining tissue samples through biopsies or post-slaughter tissue sourcing. Biopsies are typically performed using minimally invasive techniques such as needle aspiration or small tissue excision under local anesthesia to minimise animal discomfort. Post-slaughter tissue sourcing, on the other hand, may involve collecting tissues from animals slaughtered through particular methods, which can be an important consideration for some religious certifications, such as halal.

Tissue samples are collected under sterile conditions to prevent contamination and ensure cell integrity. They are immediately placed in a nutrient-rich culture medium to maintain cell viability during transit to the laboratory. The quality and handling of these samples are crucial, as any damage or contamination can compromise the success of subsequent cell isolation and culture processes. Ensuring minimal damage and maximal viability of the collected cells is essential for establishing robust cell cultures that can proliferate and differentiate effectively.

This step directly leads to cell isolation and purification, where specific cells are extracted and prepared for culture, laying the groundwork for the rest of the cultivated meat production process.

Local anesthesia kits | Transport medium | Biopsy kits | Centrifuge |

Local anesthesia kits |

Transport medium |

Biopsy kits |

Centrifuge |

Cell isolation and purification involve separating the target cell population, such as stem cells, from the collected tissue samples and purifying them for culture. These stem cells are the starting point for the cultivated meat process due to their unique capability to self-renew and differentiate into specialised cell types. Stem cells are generally categorised into two types: pluripotent stem cells and adult stem cells. The decision of which stem cell type to use depends on the ease of isolation from the source tissue, differentiation potential, and proliferative capacity, which may differ from species to species. The scale-up bioprocess and end-product goals are also important considerations for cell type choice.

Pluripotent stem cells can differentiate into any cell type in the body. They include:

Adult stem cells are more specialised and have a limited differentiation capacity compared to pluripotent stem cells. Examples of cultivated meat-relevant adult stem cell types include:

The cell isolation process begins with mechanically and enzymatically dissociating the tissue to release individual cells. Enzymes, such as collagenase or trypsin, break down the extracellular matrix and separate the cells from clumps. The resulting cell suspension undergoes purification steps, including centrifugation and filtration, to remove debris and non-target cells. Advanced techniques like flow cytometry or magnetic-activated cell sorting (MACS) use specific cell surface markers to isolate and purify the target cells with even higher precision.

The purified cells are assessed for viability using cell counting and viability staining. The goal is to obtain a highly pure and viable starting cell population that can be efficiently expanded in vitro to create a stable and robust cell line.

Enzymatic digestion equipment | Cell sorting devices (e.g., MACS) | Centrifuges |

Enzymatic digestion equipment |

Centrifuges |

Cell sorting devices (e.g., MACS) |

A primary cell culture is established after cell isolation and purification. This process involves creating an optimal environment for isolated primary cells to proliferate and form robust cultures in vitro. It begins by seeding the cells into culture vessels, such as T-flasks or round culture dishes, containing a nutrient-rich medium specifically designed to support their growth. This medium includes essential nutrients, growth factors, and hormones that mimic the natural cellular environment. The cells are evenly distributed across the two-dimensional culture surface to ensure uniform growth and nutrient access. The culture flasks are then placed in a sterile incubator set to controlled conditions, typically around 37°C with 5% CO₂ and high humidity for mammalian cells, to promote good culture health, viability, and proliferation.

Initially, cell cultures are maintained in small-scale vessels or multi-well plates. As the cells proliferate and reach confluence, they are split and passaged successively into larger vessels to accommodate a growing cell population. This involves detaching the cells using enzymatic methods, such as trypsinisation, and re-seeding them into new culture vessels at specific densities with fresh media. This process of expansion and passaging continues iteratively until a sufficient number of cells are obtained for subsequent stages.

The establishment phase is time-intensive, often taking several weeks to months, depending on the cell type and desired yield. During this period, cells undergo numerous population doublings, expanding to create a sufficient number of cells for the next steps. Parameters such as cell count, cell density, population doubling time, and cumulative number of population doublings are meticulously recorded and overall culture health is consistently monitored to mitigate risks of contamination.

Upon initial establishment, the cell cultures are typically heterogeneous and may still contain residual sub-populations of non-target cells. With time and regular passaging, the cultures become more homogeneous and exhibit many characteristics reminiscent of the original tissue, including morphology and functional properties. For instance, primary myoblasts closely resemble the muscle cells from which they were derived, while primary adipocytes exhibit traits typical of fat cells. A range of functional assays along with gene expression profiling may be performed to characterise the unique features of these cells to confirm their identity and behaviour.

Primary cell cultures are valuable for their relevance to in vivo conditions, making them crucial for initial studies and small-scale production. However, their limited lifespan and finite proliferative capacity pose challenges for large-scale cultivated meat production. To overcome these limitations, primary cell cultures often serve as a starting point for developing stable immortalised cell lines, which can proliferate indefinitely and provide a consistent and reliable cell source for large-scale production.

Culture flasks | Incubators | Bioreactors |

Culture flasks |

Incubators |

Bioreactors |

Donor animal selection is a foundational step in cultivated meat production, as it determines the source of cells and the cell types that will be isolated, cultured, and expanded to produce the final food product. The selection process begins with identifying suitable animal species and individual animals based on their genetic attributes, health status, and breed characteristics.

This selection is critical for ensuring that the cells derived from the animal tissues possess desired qualities, such as a high proliferative capacity and strong differentiation potential, which influence the consistency of the manufacturing process and the final product’s quality. A comprehensive assessment of the animal’s health is also performed to confirm that the animal is free from diseases and has a stable genetic background. This data collection is crucial, as it directly impacts the efficiency, robustness, and viability of the developed cell lines used for the rest of the cultivated meat process.

Commonly chosen species include cows, pigs, sheep, chickens, and various aquatic species such as salmon and tuna. The choice of species often aligns with market demand and the environmental impact associated with conventional meat production. The goal is to replicate advantageous traits in the cultivated meat product. For instance, specific cattle breeds like Wagyu for beef or heritage pig breeds for pork are selected to ensure the cultivated meat has taste and texture profiles similar to the highest quality conventional meat.

Genetic testing kits | Portable blood analysers |

Genetic testing kits |

Portable blood analysers |

Cell lines are established through various methods, with spontaneous immortalisation being one of the most common. This occurs when primary cells undergo genetic changes over successive passages, enabling them to proliferate indefinitely under optimal conditions. Continuous passaging involves regularly transferring cells to new culture vessels, resulting in a stable and robust growth phenotype.

Dilution techniques are often used to isolate individual cell clones from the primary cell culture for immortalisation. These methods help identify the most promising cell clones based on their proliferation rates, genetic stability, and ability to differentiate into desired tissue types. By expanding and characterising these clones, researchers can ensure the immortalisation and development of robust and reproducible cell lines.

Immortalisation allows cells to bypass the Hayflick limit, the point at which normal cells can no longer divide. This limit represents a fundamental barrier to the proliferation of primary cells in culture. Immortalised cell lines, which can divide indefinitely, are invaluable for both research and production, providing a consistent and long-term cell source across studies and batches.

Non-integrating expression approaches for immortalisation, such as Sendai virus or synthetic mRNA, avoid permanent genome alterations. For instance, Sendai virus can introduce genes that encode key transcription factors into primary cells, transforming them into immortalised cells without integrating into the host genome. Similarly, synthetic mRNA can transiently express factors that promote cell proliferation and survival.

Genetic engineering is another method for creating immortalised cell lines. By altering the DNA of primary cells, researchers can confer properties such as immortalisation, suspension growth, and low doubling time, which are essential for cultivated meat production. Techniques like Clustered Regularly Interspaced Short Palindromic Repeats (CRISPR)/Cas9 allow precise genome editing, enabling the introduction or modification of genes associated with immortalisation pathways. However, using genetically engineered cell lines requires careful consideration of regulatory and consumer acceptance issues.

Immortalised cell lines are crucial for both research and large-scale production phases, offering a consistent and reliable foundation for experimentation, product development, and manufacturing.

Molecular biology (e.g., polymerase chain reaction (PCR), sequencers) tools | High-throughput screening systems | Automated cell counters |

Genetic engineering tools (e.g., CRISPR) | Biosafety cabinet |

Molecular biology (e.g., polymerase chain reaction (PCR), sequencers) tools |

High-throughput screening systems |

Automated cell counters |

Genetic engineering tools (e.g., CRISPR) |

Biosafety cabinet |

QA/QC in cultivated meat production involve cell characterisation to ensure the integrity and quality of immortalised cell lines. This process validates the cell lines’ suitability for subsequent proliferation and differentiation.

Cell characterisation includes viability, purity, traceability, and safety assessments. Viability assessments determine the percentage of living cells within the culture, to ensure enough viable cells are available for further cultivation. Purity assessments verify the homogeneity of the cell population, to confirm that it consists primarily of the desired cell type and species without contamination from other cell types or microorganisms. Traceability assessments track the origin and lineage of the cells. Safety assessments may involve ensuring the cells are free of viruses, pathogens, or other common laboratory contaminants such as Mycoplasma.

Advanced analytical techniques such as microscopy, flow cytometry, and molecular analysis methods are employed for these assessments. Microscopy provides visual inspection of cell morphology and overall culture health. Flow cytometry allows for quantitative analysis of cell populations based on specific surface markers or fluorescent dyes, thereby facilitating precise determination of viability and purity. Molecular analysis techniques, including polymerase chain reaction (PCR) and immunostaining, offer further insights into cell characteristics. Karyotyping provides valuable information about chromosomal abnormalities and structural variations. Transcriptomic analysis profiles the entire set of RNA transcripts expressed by the cells, which reveals gene expression patterns and regulatory networks. Whole genome sequencing provides a comprehensive view of the cell’s DNA sequence, mutations, genetic variants, and alterations in key regulatory regions.

Specific characteristics are evaluated to ensure the quality and functionality of the cell cultures. These include non-adherent growth in suspension, strong differentiation potential towards target cell types, high proliferation rate with a doubling time of less than 24 hours, genetic stability across multiple generations, and metabolic efficiency. Additionally, resilience to shear stress and limited accumulation of toxic metabolic byproducts such as ammonia are essential for robust cell culture systems.

Quality control measures are implemented at each step of the cell characterisation process to ensure consistency and reliability. Standard operating procedures (SOPs), equipment calibration, and analytical method validation ensure the validity of the data generated. QA/QC allows researchers to maintain the quality and integrity of immortalised cell lines, thereby supporting the development of reliable cell banks.

Flow cytometers | Contamination detection systems | Safety equipment |

Flow cytometers |

Contamination detection systems |

Safety equipment |

Cell banking is essential for maintaining a consistent and reliable source of cells for large-scale cultivated meat production. Establishing master and working cell banks mitigates the risks of genetic drift, which is vital for reproducible and high-quality cultivated meat.

Master Cell Banks (MCBs) are created by expanding a select group of cells that have undergone rigorous quality control and validation to ensure they possess the desired growth and differentiation properties. These cells are cryopreserved in small aliquots using optimised, chemically-defined cryopreservation techniques to preserve their genetic stability and functionality over time. MCBs serve as a long-term, stable source of cells, preventing the issues associated with genetic drift, such as single nucleotide polymorphisms, copy number variations, large insertions or deletions, epigenetic changes, or aneuploidy.

Cryopreservation techniques involve storing cells at ultra-low temperatures in liquid nitrogen to preserve their viability and functionality. Proper handling and storage protocols are followed to prevent contamination and ensure the integrity of the cell banks.

Working Cell Banks (WCBs) are derived from MCBs and are used for routine production. WCBs provide a consistent and high-quality cell source and ensure that the cells used in production are identical in their properties and performance. This consistency is crucial for reproducibility and scalability in cultivated meat production, as it ensures that any variations in the cell populations do not affect the final product quality. This strategy allows for batch or continuous processing of stem cells, so that cultures can be restarted if significant genetic or performance differences are detected.

Regular testing and monitoring of cell banks are conducted to verify the stability and quality of the stored cells. This includes viability assays, genetic stability assessments, and sterility tests to ensure the cells remain suitable for use in production. By maintaining a robust cell banking system, the cultivated meat industry can provide a reliable and consistent supply of high-quality cells and support ongoing production and scalability.

Cryopreservation systems | Liquid nitrogen freezers |

-80℃ freezers | Cryoprotective agents |

Cryopreservation systems |

Liquid nitrogen freezers |

-80℃ freezers |

Cryoprotective agents |

Following cell banking, seed train development is employed to scale up cultivated meat production. This process gradually transitions cells from small-scale starter cultures to large-scale bioreactors. Skipping the seed train and inoculating a large bioreactor directly from a working cell bank vial can lead to delayed growth, increased risk of contamination, inefficiency, and potentially compromised product quality. The seed train process is critical for growing healthy cells at an optimal density to proliferate efficiently in larger volumes.

The seed train process begins with a single vial of cells from a working cell bank, which is thawed and cultured in small flasks or spinner cultures. As cells proliferate and reach higher densities, they are transferred to progressively larger vessels, such as shake flasks, wave bags, or small-scale bioreactors. This step-wise expansion allows cells to adapt gradually to increasing volumes from millilitres in small flasks to litres in intermediate vessels and finally to hundreds or thousands of litres in large-scale bioreactors. The cells adapt to each new environment while maintaining their growth characteristics and functionality.

During seed train development, cells undergo several phases: a lag phase, where they adapt to the new environment; a log phase characterised by exponential growth; and a stationary phase. The starting cell density and culture volume influence nutrient availability and the time required to reach the log phase. Efficient seed train development aims for rapid and steady log phase growth, which is crucial for minimising time and cost without compromising downstream differentiation potential or cell viability.

Different optimisation strategies can be used to achieve this. For instance, high-density cryopreservation allows cells to be thawed directly into multi-litre bioreactors, reducing scaling time and costs. Continuous or semi-continuous bioprocessing, coupled with advanced cell retention devices, enables high-density cell growth while minimising downtime between runs. Unlike traditional seed trains that require multiple passages and time-consuming expansion steps, hollow fibre bioreactors can streamline the process by enabling cells to reach the desired density within a single bioreactor system, thus reducing overall process time.

During this expansion, key parameters such as nutrient concentration, pH, temperature, and oxygen levels are meticulously controlled to maximise cell yields.

Efficient seed train development is essential for generating the high-density cell cultures needed for large-scale bioprocessing and ensuring a consistent and reliable supply of cells for primary bioreactor proliferation.

Cryostorage (nitrogen) tanks | Centrifuges and incubators | pH and DO sensors/controllers |

Flasks/bioreactors | Autoclaves | Controlled-rate freezers |

Cryostorage (nitrogen) tanks |

Centrifuges and incubators |

pH and DO sensors/controllers |

Flasks/bioreactors |

Autoclaves |

Controlled-rate freezers |

Primary bioreactor proliferation is focused on significantly expanding the number of cultured cells to achieve the high cell densities necessary for subsequent tissue formation. Proliferation refers to the rapid multiplication of cells, where each cell divides to produce two daughter cells, exponentially increasing the cell population. This process takes place in large-scale bioreactors, specifically designed to support and maintain optimal conditions for cell growth.

Cells are initially inoculated into the primary bioreactors following their expansion in the seed train; a process that gradually increases cell numbers in preparation for large-scale culture. Once inside the primary bioreactors, the cells are continuously monitored using advanced sensors and control systems. These systems track vital parameters, such as cell density, nutrient consumption, temperature, pH, dissolved oxygen levels, and metabolic activity, enabling real-time adjustments to optimise growth conditions and maximise cell yield.

The design of primary bioreactors is tailored to achieve high cell densities, which are crucial for cultivated meat production. Bioreactors may incorporate various technologies, such as rocking platforms, stirred-tank systems, or perfusion bioreactors, each selected based on the specific needs of the cell type and desired production scale. The goal is to create an environment that supports robust cell proliferation while minimising stress and ensuring cells retain their ability to differentiate into the desired tissue.

This stage is foundational for the entire production process, as it generates the proliferated cells necessary for subsequent stages of differentiation and maturation. Once the cells have reached the desired density and viability, they are harvested from the primary bioreactors and depending on the final product, cells may be transferred to secondary bioreactors. In these secondary systems, the cells undergo further development, transitioning from a proliferative state to differentiated tissue that closely mimics the structure and function of conventional meat.

In summary, primary bioreactor proliferation is a vital step that ensures a consistent and abundant supply of cells and sets the stage for successful differentiation and maturation.

Monitoring and control systems | Large-scale bioreactors | Scaffolds |

Novel harvesting systems | Centrifuges |

Monitoring and control systems |

Large-scale bioreactors |

Scaffolds |

Novel harvesting systems |

Centrifuges |

Secondary bioreactor inoculation is where proliferated cells from primary bioreactors are transferred into specialised secondary bioreactors designed to guide these cells through the process of differentiation and maturation. Differentiation refers to the biological process by which unspecialised cells, typically stem cells or progenitor cells, develop into specialised cell types with distinct functions. In the context of cultivated meat, the primary goal of differentiation after proliferation is to generate the three key cell types necessary for replicating the structure and functionality of conventional meat: muscle tissue, adipose tissue, and connective tissue.

The process begins with the careful seeding of secondary bioreactors, which often contain scaffolds that support the cells as they transition from a proliferative state to differentiated tissue. These scaffolds mimic the extracellular matrix (ECM) found in natural tissues, providing a framework that guides cellular organisation and development. High-density cell cultures harvested from the primary bioreactors are introduced into the scaffold-containing secondary bioreactors under tightly controlled conditions.

The secondary bioreactor is engineered to simulate the natural in vivo conditions that cells would experience in an organism, thereby encouraging proper tissue formation. Dynamic mechanical stimulation, biophysical cues, and biochemical signals are all integrated into the bioreactor’s design to support the differentiation process. For example, mechanical forces can be applied to encourage muscle fibre alignment, while specific nutrients and oxygen levels are adjusted to promote the growth of adipose and connective tissues.

Throughout this stage, the bioreactors are equipped with advanced monitoring systems that continuously assess the culture conditions. Key parameters such as cell density, nutrient consumption, and waste production are closely monitored, and any necessary changes to the environment are made to optimise the quality and functionality of the developing tissues.

Successful secondary bioreactor inoculation is crucial for producing structured tissues that closely replicate the texture, flavour, and overall sensory experience of conventional meat.

Secondary bioreactors | Biochemical supplement systems | Mechanical and electrical stimulation devices |

Secondary bioreactors |

Biochemical supplement systems |

Mechanical and electrical stimulation devices |

Bioprocess optimisation in the context of secondary bioreactors focuses on fine-tuning conditions to maximise the efficiency and quality of tissue differentiation and maturation. This involves continuous monitoring and adjustment of key parameters, including nutrient gradients, gas exchange, and mechanical forces applied to the developing tissues. Advanced control systems and sensors are used to maintain optimal conditions and ensure uniform growth across the entire bioreactor. Computational models and in silico simulations may be employed to predict and optimise the behaviour of cells within the bioreactor, guiding adjustments to the bioprocess. The goal is to achieve high yields of mature, functional tissues that closely resemble those found in conventional meat products. Effective bioprocess optimisation ensures that the tissues produced are consistent, high-quality, and suitable for subsequent harvesting and processing. This stage also involves the integration of feedback mechanisms to continuously improve and refine the bioprocess based on real-time data and experimental outcomes. Optimised bioprocess conditions are essential for differentiation and maturation, where cells develop into functional tissues ready for harvest.

Bioreactors | Sensors and control systems | Analytical instruments |

Bioreactors |

Sensors and control systems |

Analytical instruments |

With immortalised cell lines established, producers then develop the most effective culture media tailored to each specific cell type. Cell culture media formulation involves selecting ingredients to provide essential nutrients, growth factors, and signaling molecules for cell proliferation, maintenance, and differentiation. Different cell types have unique nutrient requirements, necessitating customised media formulations. For example, muscle cells may require higher concentrations of certain amino acids or growth factors compared to other cell types.

Basal media, forming the foundation of cell culture media, typically consist of a buffered solution with glucose, inorganic salts, water-soluble vitamins, and amino acids. These components sustain basic cellular functions and metabolic processes. Specific added factors further support cell growth and enhance proliferation or differentiation. These often include recombinant proteins, growth factors, or hormones that stimulate natural signaling pathways. Lipids and antioxidants may also be included to support cell membrane integrity and protect against oxidative stress.

Ongoing developments aim to improve the cost-effectiveness, scalability, and sustainability of media formulations. Key areas include reducing reliance on animal-derived components, optimising the production of recombinant proteins and growth factors, and sourcing media components at food or feed grade to minimise costs and ensure quality.

Eliminating fetal bovine serum (FBS) is crucial in cell culture media for cultivated meat production. FBS raises ethical, economic, and regulatory concerns. The industry is transitioning to serum-free media formulations, aligning with trends towards animal-free alternatives.

Advancements in metabolic modelling and computational algorithms can aid in discovering and optimising media formulations by predicting nutrient requirements and metabolic pathways in cultured cells. High-throughput screening techniques and microfluidic platforms offer valuable tools for rapid formulation discovery and optimisation.

Cell culture media play a pivotal role in supporting cell growth and proliferation in cultivated meat production. By providing necessary nutrients and growth factors, media formulations create an environment conducive to cell growth, enabling the production of high-density cell populations required for subsequent processing. As the cultivated meat industry evolves, advancements in cell culture media technology will be essential for driving innovation and achieving scalability and sustainability.

Biochemical analysers | Sterile filtration units |

Biochemical analysers |

Sterile filtration units |

Supply chain optimisation is essential for ensuring the efficient and reliable delivery of materials and resources required for cell line development and large-scale cultivated meat production. This stage involves streamlining procurement processes, managing inventory, and establishing robust logistics to support uninterrupted production.

With cell lines developed and cell culture media optimised, it then becomes necessary to source high-quality raw materials from reputable suppliers, such as culture media components, growth factors, and bioreactor supplies. Maintaining production continuity is crucial to establishing strong relationships with suppliers and developing contingency plans to mitigate supply chain disruptions.

Inventory management systems are implemented to monitor stock levels and optimise storage conditions for sensitive materials. Advanced forecasting techniques and just-in-time inventory practices help reduce waste and ensure the timely availability of essential supplies.

Logistics optimisation focuses on reducing transportation time and costs while maintaining the integrity of materials during transit. This includes selecting appropriate shipping methods, ensuring proper packaging, and coordinating with logistics partners for timely deliveries.

Supply chain optimisation also involves compliance with regulatory requirements and industry standards, ensuring that all materials and processes meet quality and safety standards.

Inventory management systems | Cold storage units | Logistics software |

Inventory management systems |

Cold storage units |

Logistics software |

In cultivated meat production, scaffolds are crucial structures that mimic the microenvironment of native tissues and guide the growth and organisation of cultured cells into meat products. These frameworks replicate the extracellular matrix (ECM) found in living tissues by providing a supportive environment for cell attachment, migration, proliferation, and differentiation. If kept in the final product, scaffolds also play a role in replicating the texture of conventional meat.

To effectively support different cell types, scaffolds must meet specific criteria, including porosity, mechanical properties, and biochemical cues. Porosity allows for nutrient and oxygen diffusion, waste removal, and cell communication. Mechanical properties ensure that scaffolds can withstand stresses and provide necessary support. Biochemical cues, such as growth factors and adhesion peptides, regulate cell behaviour and promote tissue differentiation.

Scaffolds can be categorised into five main types: microcarriers, small beads that support adherent cell growth in suspension; porous scaffolds, which have a sponge-like structure ideal for cell infiltration; hydrogels, networks of polymers that absorb significant amounts of water and provide a soft, hydrated environment; additive approaches such as 3D printing, which allows precise control over scaffold architecture; and fibre scaffolds, which offer aligned structures for guiding cell growth and tissue formation

A variety of materials are used for scaffold fabrication. Natural polymers like collagen and gelatin are biocompatible and bioactive, closely resembling natural ECM components, and recombinant versions of these polymers made through precision fermentation can ensure an animal-free product. Synthetic polymers, such as polylactic acid (PLA) and polyglycolic acid (PGA), offer customisable mechanical properties and degradation rates. Plant-based materials, like soy protein, alginate, or cellulose, offer a lower cost of development and potential high compatibility with the requirements of food products. Hybrid materials combine the strengths of both to provide enhanced stability and bioactivity.

Advanced fabrication techniques, including 3D printing, stereolithography, laser-assisted bioprinting, droplet-based bioprinting, and electrospinning, allow for precise control over scaffold architecture and mechanical properties. These techniques enable the creation of scaffolds tailored to the needs of different cell types and tissues. For example, scaffolds for muscle cells may feature aligned fibres to replicate native muscle tissue, while those for adipose tissue may require softer structures to mimic fat depots. Alternatively, native tissue architecture from decellularised animal-, plant-, or fungal-tissue can be used as a scaffold.

Scaffolds are integrated into bioreactors during the cultivation process to ensure that they are positioned correctly for even cell distribution, nutrient flow, and waste removal. This integration requires careful consideration of how scaffolds interact with the cultured cells and the bioprocess environment, including temperature, pH, and mechanical forces.

Scaffolds also influence the flavour, texture, and other characteristics of the final product. The distribution of fat, muscle fibres, and connective tissue within the scaffold affects the texture and mouthfeel, making it essential to optimise scaffold design and material properties to achieve high-quality, functional meat products that closely mimic conventional meat.

3D printers | Electrospinning devices | Bioreactors | Texture analysers |

3D printers |

Electrospinning devices |

Bioreactors |

Texture analysers |

Automation and intensification are crucial for efficiently scaling up cultivated meat production. Automated systems manage key processes like nutrient feeding, gas exchange, agitation, and harvesting, thereby reducing manual intervention and ensuring consistent results. Real-time sensor data enables automated adjustments to maintain optimal culture conditions throughout the production cycle.

Incorporating automation offers significant cost savings by reducing labour, minimising reagent use, optimising lab space, and standardising quality control. Automation also enhances contamination prevention and simplifies regulatory compliance in closed systems. While automation is progressing in fields like cell therapy, cultivated meat production’s scale requires substantial engineering customisation, particularly in cell scaling, quality control, harvesting, and product formulation.

Drawing on automation practices from established bioprocess industries, such as food and agriculture, can benefit cultivated meat production. However, automation should be integrated from the outset rather than retrofitted. Collaborative efforts are needed to develop cost of goods sold (COGS) models, which can identify bottlenecks in the process that could benefit from automation.

Automated bioreactors | Control systems | Automated sampling | Liquid handling system |

Automated bioreactors |

Control systems |

Automated sampling |

Liquid handling system |

In silico modelling is a powerful tool for optimising cultivated meat production processes. Computational algorithms and models simulate various scenarios to predict nutrient requirements, metabolic pathways, and optimal culture conditions. These models help identify the most efficient strategies for scaling up production, which can save time and resources.

Metabolic modelling predicts how cells will respond to different nutrient concentrations and environmental conditions, which informs the design of tailored media formulations. Computational fluid dynamics (CFD) models simulate the behaviour of cells and media within bioreactors and enable producers to optimise parameters such as mixing, oxygen transfer, and nutrient distribution.

In silico modelling also assists in selecting bioprocessing methods by predicting the accumulation of paracrine signals and identifying strategies to enhance cell proliferation and differentiation. Integrating these models with real-time data from bioreactor monitoring systems allows researchers to make informed adjustments to optimise cell growth and productivity.

High-performance computer | Modelling software | Data analytics tools |

High-performance computer |

Modelling software |

Data analytics tools |

The differentiation and maturation stage is where proliferated cells develop into fully functional muscle, connective, and fat tissues, which is essential for replicating the texture, structure, and functionality of conventional meat. Differentiation is triggered by altering the culture media to include specific biochemical cues, such as growth factors and signaling molecules, which guide cells to form the desired tissue types. Mechanical stimulation, like cyclic stretching or electrical pulses, is also applied to mimic natural physiological conditions, enhancing tissue formation. This stage is crucial for developing the characteristics that make cultivated meat comparable to conventional meat, including its texture, structure, and nutritional profile. The primary goal of differentiation is to generate the three key cell types:

Throughout this stage, extensive characterisation and quality control measures are conducted to ensure that the differentiated tissues meet safety, quality, and functionality standards. Mature tissues are then harvested for further processing to ensure they meet the desired characteristics before entering the final product development stage.

Differentiation bioreactors | Biochemical supplement systems |

Mechanical and electrical stimulation devices |

Differentiation bioreactors |

Biochemical supplement systems |

Mechanical and electrical stimulation devices |

The harvest stage involves carefully extracting mature tissues from the bioreactors. This process must be conducted under sterile conditions to prevent contamination and ensure the integrity of the final product. The harvested tissues are separated from any remaining culture media, cleaned, and prepared for further processing. Harvesting directly impacts the quality and yield of the cultivated meat, therefore proper techniques and equipment are essential to minimise tissue damage.

Harvested tissues are now the raw materials for food formulation, where they are processed and combined with other ingredients to create final cultivated meat products. The harvested tissue must undergo extensive testing and quality control to ensure that it is contaminant-free and meets the required safety and quality standards for subsequent processing and commercialisation.

Harvesting tools | Sterile containers | Processing equipment |

Harvesting tools |

Sterile containers |

Processing equipment |

Food formulation for the cultivated meat produced today is focused on creating less structured hybrid products. This involves the process of developing recipes and formulations that combine the harvested cultivated meat with other ingredients to create the final product. This step involves extensive experimentation to achieve the desired taste, texture, and nutritional profile. The formulation must consider factors such as flavour, mouthfeel, appearance, and cooking properties. Food scientists work to optimise the blend of cultivated meat with plant-based ingredients, fats, flavourings, and binders to create a product that closely mimics conventional meat. This stage is critical for ensuring that the final product appeals to consumers and meets their expectations for taste and quality. The formulations are tested through sensory analysis and adjusted based on feedback to refine the product. The goal is to develop a product that not only replicates the sensory experience of conventional meat but also offers additional benefits such as improved nutritional content or environmental sustainability. This stage also involves extensive testing and optimisation to ensure that the formulated products meet all regulatory requirements and consumer expectations. Formulated products undergo sensory analysis and product optimisation to refine their characteristics and ensure they meet consumer expectations.

Further down the road, when we are able to create whole-cut cultivated meat products that are analogous to whole-cut conventional meat products, it is anticipated that the formulation will essentially take place during the culture period, and the final step will be harvesting, aging, and packaging of a whole-cut tissue that is ready for consumption.

Mixing equipment | Flavour and ingredient scales | Formulation tools |

Mixing equipment |

Flavour and ingredient scales |

Formulation tools |

Consumer testing and sensory analysis are crucial steps in the product development cycle for alternative protein products. The primary goals are to assess how well the product aligns with consumer preferences, identify areas for improvement in flavour, texture, aroma, appearance, and overall appeal, and gather insights into potential market reception.

Sensory attributes typically evaluated include:

Sample sizes and testing methodology: Testing usually involves a mix of trained sensory panels and a larger group of untrained consumers representing the target audience. The size of the consumer panel can range from 50 to several hundred participants, depending on the scope of the test. Trained panels often include 10-20 experts, while larger consumer tests might involve 100-200 participants for more comprehensive feedback.

Participants are typically asked to rate each attribute on a scale (e.g., 1-10) or provide qualitative feedback. Common methods include:

Data from these tests are analysed both statistically and qualitatively. Statistical analysis helps identify trends, correlations, and significant differences between product variants. Qualitative insights provide context to the numerical data, offering deeper understanding of consumer preferences.

Based on the results, the product formulation may be adjusted, followed by further rounds of testing. This iterative approach ensures that the final product is fine-tuned to meet consumer expectations, increasing its chances of market success. By systematically gathering and analysing feedback, manufacturers can make informed decisions that enhance the product’s appeal and ensure it resonates with the intended market segment.

Sensory testing booths | Gas chromatography | Mass spectrometry | E-tongue instruments |

Sensory testing booths |

Gas chromatography |

Mass spectrometry |

E-tongue instruments |

Quality assurance (QA) in cultivated meat production involves implementing systematic processes to ensure that products meet predefined quality standards throughout the manufacturing process. QA activities include developing and enforcing standard operating procedures (SOPs), conducting regular audits and inspections, and implementing preventive measures to avoid defects and ensure product consistency. QA teams work closely with production and quality control (QC) teams to monitor critical control points and address any issues that arise. This step ensures that the final product is safe, high-quality, and meets consumer expectations, thereby maintaining brand integrity and regulatory compliance. Continuous improvement initiatives are undertaken to enhance product quality and operational efficiency. QA plays a vital role in maintaining the trust and satisfaction of consumers and ensuring the long-term success of the cultivated meat product in the market.

QC focuses on inspecting and testing the final product to ensure it meets the established quality standards and specifications. QC activities include sampling products at various stages of production, performing laboratory tests to check for contaminants and nutritional content, and conducting sensory evaluations to assess taste, texture, and appearance. Any deviations from quality standards are documented, and corrective actions are taken to address the issues. QC ensures that only products that meet the highest quality criteria reach the market, which is vital for maintaining consumer trust and satisfaction. The QC team works closely with the manufacturing and QA teams to ensure that all quality standards are met.

Microbiological testing kits | Sensory evaluation tools | Nutritional analysers |

Microbiological testing kits |

Sensory evaluation tools |

Nutritional analysers |

Post-processing involves additional steps to enhance the texture, flavour, and appearance of the cultivated meat products. Texturing techniques, such as extrusion and tumbling, are used to create the fibrous structure and mouthfeel characteristics of conventional meat. Flavouring involves the addition of spices, seasonings, and marinades to enhance the taste and aroma of the product. Post-processing also includes steps such as smoking, cooking, aging, or drying to achieve the desired flavour profile and shelf life. The goal is to create a product that not only mimics the sensory experience of conventional meat but also offers additional benefits such as improved nutritional content or unique flavour profiles. Post-processing, texturing, and flavouring are critical for ensuring that the final product meets consumer expectations and is competitive in the market.

Extruders | Smokers | Marination equipment |

Extruders |

Smokers |

Marination equipment |

The labelling and packaging processes are crucial to bringing cultivated meat products to market and ensuring that consumers are informed about a product’s unique characteristics. Firstly, accurate ingredient labelling and nutritional information needs to be ensured. Adherence to local and international regulations regarding food labelling includes providing information on ingredient lists, allergens, batch coding, expiration dates, certifications, and serving size suggestions. Furthermore, providing comprehensive nutritional information, including protein content, vitamins, minerals, and other relevant details will be required. It is also important that instructions on storage conditions and handling (e.g., freezing, cooking, and refrigeration) ensure that consumers maintain the product’s quality and safety. Lastly, market-informed packaging is essential for capturing consumer attention. The labelling and packaging process is not only about providing information but also about creating a trustworthy brand image.

Packaging machines | Label printers | Sealers |

Packaging machines |

Label printers |

Sealers |

Manufacturing involves scaling up the production process to produce cultivated meat products at a commercial scale. This step involves optimising and streamlining the production process to ensure efficiency, consistency, and cost-effectiveness. Manufacturing facilities are designed to meet high standards of hygiene and safety, with specialised equipment and technologies for large-scale production. The manufacturing process includes cell culture, bioreactor operation, tissue harvesting, and post-processing. Each step is carefully monitored and controlled to ensure product quality and safety. Manufacturing also involves implementing good manufacturing practices (GMP) and adhering to regulatory requirements. Scaling up production requires significant investment in infrastructure, equipment, and personnel, as well as ongoing optimisation and innovation to improve efficiency and reduce costs. The goal is to produce cultivated meat products at a scale that meets market demand while maintaining the highest standards of safety and quality. This stage is critical for bringing the product to market and achieving commercial success. Manufactured products are distributed for final product sales, reaching consumers through various retail and foodservice channels.

Production lines | Cooking equipment | Automation systems |

Production lines |

Cooking equipment |

Automation systems |

The final stage involves distributing the finished cultivated meat products to retailers, foodservice providers, and direct-to-consumer channels. This step includes logistics planning to ensure timely and efficient delivery, inventory management to maintain adequate stock levels, and sales strategies to promote the products. Effective distribution and sales are crucial for maximising market reach and consumer adoption. This stage also involves gathering feedback from retailers and consumers to inform future product development and marketing efforts. Ensuring that the products are available, accessible, and appealing to consumers is key to the success of the cultivated meat brand. Distribution channels are carefully selected to optimise market reach and efficiency. Sales strategies are developed to promote the products and attract consumers.

Point-of-sale systems | Marketing tools | Distribution logistics |

Point-of-sale systems |

Marketing tools |

Distribution logistics |

Food safety and regulatory compliance are crucial for ensuring that alternative protein products meet the highest standards of safety and legality before reaching the market. This process involves rigorous safety assessments, certification processes, and regulatory submissions that vary depending on the country and region. For novel products—such as those developed through cellular agriculture—regulatory approval can be especially challenging, requiring extensive testing to demonstrate safety and efficacy. This includes toxicology studies, allergenicity testing, and assessments of the nutritional profile.

Regulatory approval timelines can differ significantly across countries. For instance, the United States Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) have distinct protocols and requirements for novel food ingredients. In some cases, products may need to undergo a Generally Recognised as Safe (GRAS) determination in the U.S., or gain novel food approval in the EU. These processes involve comprehensive dossiers that document the safety, composition, and intended use of the product, and can take several years to complete.

Food safety is ensured through compliance with guidelines that identify and mitigate potential hazards in the production process. Specialised equipment is used to monitor critical parameters and ensure that products are free from contaminants and meet quality standards. Regulatory submissions require detailed documentation of the manufacturing process, ingredient sourcing, and safety testing results.

Achieving food safety and regulatory compliance is essential not only for protecting consumers but also for securing the product’s marketability. Products that successfully navigate these rigorous processes are then prepared for the next stages, including quality assurance and post-processing.

Regulatory compliance software | Documentation systems | Certification tools |

Regulatory compliance software |

Documentation systems |

Certification tools |

Cell Biologists are fundamental to the cultivated meat industry by focusing on understanding and optimising the growth and behaviour of cells used in meat production. They study cell metabolism, growth conditions, and genetic characteristics to ensure that the cells are healthy, productive, and capable of differentiating into desired tissue types. Their responsibilities include developing and maintaining cell cultures, optimising growth media, and performing genetic modifications to enhance cell performance.

In their daily operations, Cell Biologists isolate and characterise different cell strains, monitor cell growth and viability, and optimise culture conditions to support large-scale production. They work closely with Bioprocess Engineers to ensure cells perform well in bioreactors and with Tissue Engineers to develop scaffolds that support cell growth. Their projects often involve genetic engineering, metabolic profiling, and high-throughput screening to identify and optimise the best cell lines for production.

The end goal for a Cell Biologist is to develop robust, high-yield cell lines that produce cultivated meat efficiently. They need strong analytical skills, proficiency in molecular biology techniques, and a deep understanding of cell physiology and genetics. Technical skills in cell culture, genetic manipulation, and bioinformatics are crucial for their role.

Job Role and Functions: Quality Assurance (QA) and Quality Control (QC) professionals are critical in maintaining the safety, efficacy, and consistency of cultivated meat products. QA focuses on preventing defects through process improvement and adherence to quality standards, while QC involves testing products to ensure they meet specified criteria. Their responsibilities include developing quality management systems, conducting audits, and performing routine product testing.

In their daily operations, QA/QC professionals design and implement quality management protocols, conduct inspections and audits of production processes, and test samples of raw materials and finished products. They work closely with production teams to ensure that quality standards are maintained throughout the manufacturing process and with Regulatory Affairs to ensure compliance with regulations. Their projects often involve developing Standard Operating Procedures (SOPs), conducting root cause analysis of quality issues, and implementing corrective actions.

The end goal for QA/QC professionals is to ensure that all cultivated meat products are safe, effective, and of high quality. They need strong analytical skills, attention to detail, and a thorough understanding of quality management principles. Technical skills in analytical chemistry, microbiology, and quality management systems are essential for their role.

Tissue Engineers are crucial in developing the structural components of cultivated meat. They work on creating scaffolds and matrices that support cell attachment, growth, and differentiation, mimicking the natural environment of animal tissues. Their role involves designing biocompatible materials and optimising conditions to ensure that cells can form structured tissues that resemble conventional meat.

On a daily basis, Tissue Engineers conduct experiments to test different scaffold materials and their interactions with cells. They collaborate with Cell Biologists to understand the cellular requirements and with Bioprocess Engineers to integrate these scaffolds into larger production systems. Their projects often involve using advanced techniques like 3D printing, electrospinning, and hydrogel synthesis to create scaffolds that promote cell alignment and tissue formation.

The end goal for a Tissue Engineer is to develop scaffolds that enable the production of high-quality, structured cultivated meat products. They need expertise in materials science, cell biology, and engineering principles. Skills in biomaterials development, tissue engineering techniques, and cell culture are essential for their role, as well as the ability to innovate and solve complex biological problems.

Bioprocess Engineers design and optimise the processes that turn cells into meat products. They focus on developing scalable and efficient systems for cell culture, including bioreactors and fermentation processes. They ensure that conditions for cell growth are optimal, such as maintaining the correct temperature, pH, and nutrient supply, to maximise cell proliferation and differentiation.

In their daily operations, Bioprocess Engineers collaborate closely with Cell Biologists to understand the specific requirements of the cell lines being used. They are responsible for scaling up the production from laboratory settings to pilot and commercial scales, while ensuring consistency and quality throughout the process. This involves troubleshooting, optimising bioprocess parameters, and integrating automation for efficiency and reproducibility.

The end goal for a Bioprocess Engineer is to develop robust, cost-effective, and scalable processes that can produce high-quality cultivated meat. They need to have a deep understanding of chemical engineering principles, cell biology, and process control. Skills in bioreactor design, process optimisation, and data analysis are crucial for their role, as is the ability to work collaboratively with multidisciplinary teams.

Professionals in Regulatory Affairs are essential for ensuring that the processes and products in the cultivated meat industry comply with all relevant regulations and standards. They navigate the complex landscape of local, national, and international regulations to ensure that cultivated meat products are safe and legally compliant. Their responsibilities include preparing and submitting regulatory documents, coordinating with regulatory bodies, and keeping the company updated on regulatory changes.

On a daily basis, Regulatory Affairs professionals gather and compile data on product safety, efficacy, and quality. They work closely with quality assurance teams to ensure that all processes meet regulatory standards and with R&D teams to ensure that new products are developed in compliance with regulatory requirements. Their projects often involve conducting risk assessments, managing regulatory submissions, and overseeing product labelling and marketing to ensure compliance.

The end goal for Regulatory Affairs professionals is to achieve regulatory approval for cultivated meat products and maintain compliance throughout the product life cycle. They need strong analytical and organisational skills, a thorough understanding of regulatory frameworks, and the ability to communicate effectively with regulatory authorities. Technical skills in regulatory documentation, risk assessment, and compliance auditing are essential.